Bold Colors, Built The Versatrans Way.

DTF VersaColor Transfers are engineered for fine detail, bright and vibrant colors with a soft, smooth touch.

Your Design. Our Precision. Perfect Results.

Versatrans has made investments into the latest and greatest state of the art DTF printers to stand out from its competition delivering the highest quality DTF VersaColor Transfers in the industry.

Highlights of VersaColor®

Why Choose DTF VersaColor?

We named it VersaColor for a reason. Our advanced color matching technology delivers bright colors, sharp detail, professional quality making VersaColor the most versatile and reliable DTF transfer available today.

Why VersaColor®?

Your Best Work Starts With Versatrans.

Your Best Work Starts With Versatrans.

DTF built for speed and simplicity. Quick, clean, reliable digital prints.

Best For:

- Everyday cotton, poly blend garments and low melt materials (non-woven polypropylene).

- Low volume production.

- No Minimums. Unlimited Colors.

- Always 3¢ per square inch.

- Easy to use gang sheet builder.

- Same day turnaround when submitted by 1 pm est.

Application

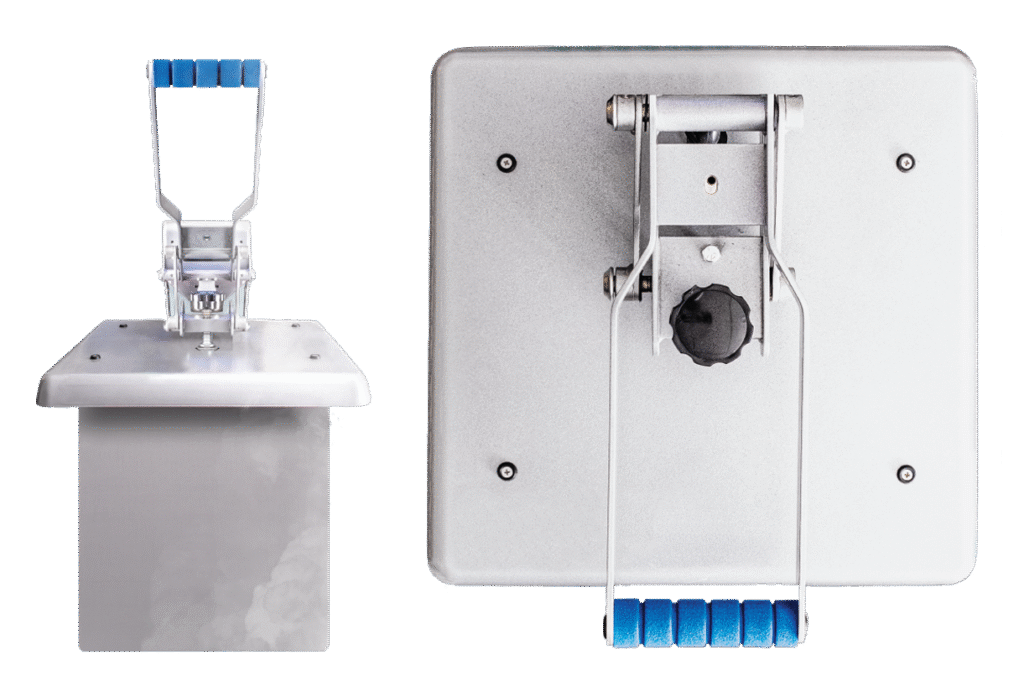

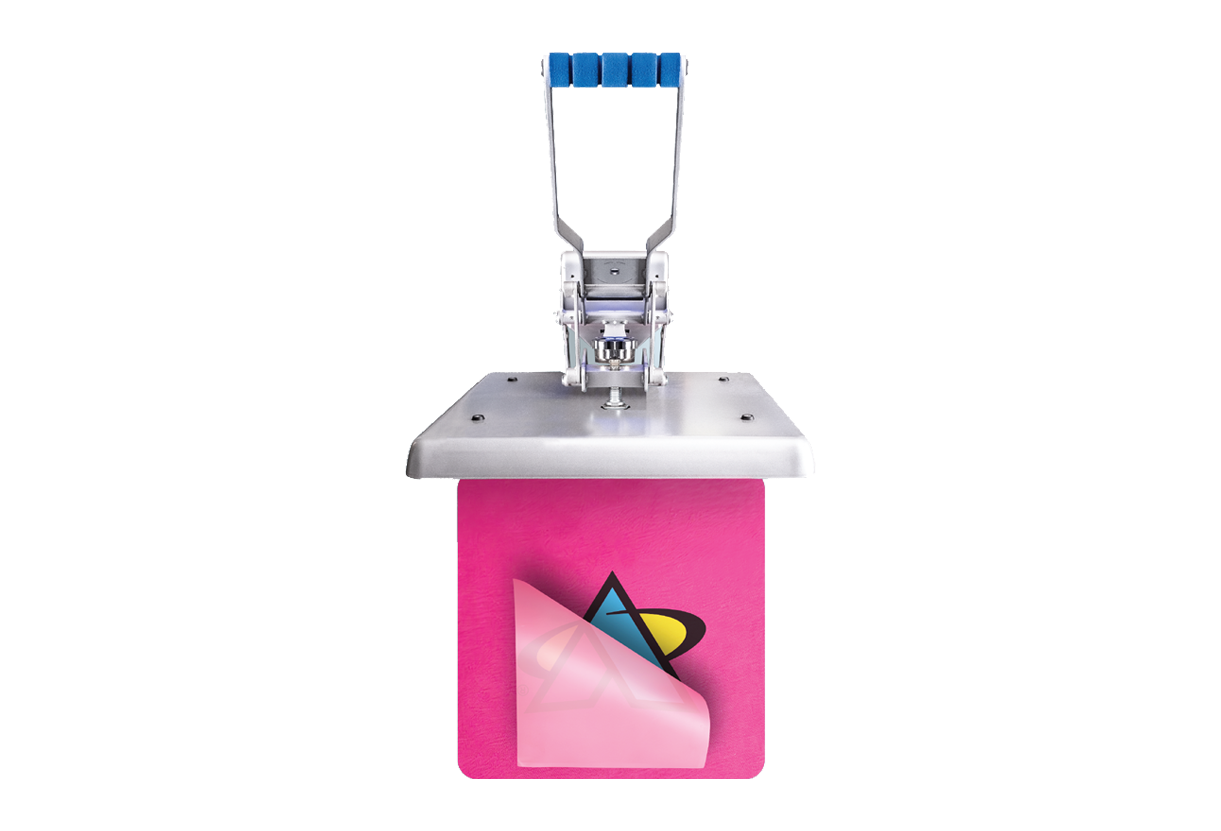

Press Like A Pro.

Always use a commercial heat press.

1. Pre-Press Platen

3 cycles at 320˚F/160˚C

Medium/Heavy pressure (6-8)/60-80 PSI

For 15 seconds.

2. Adjust Press Settings

Set heat, pressure, and time according to settings dictated by material.

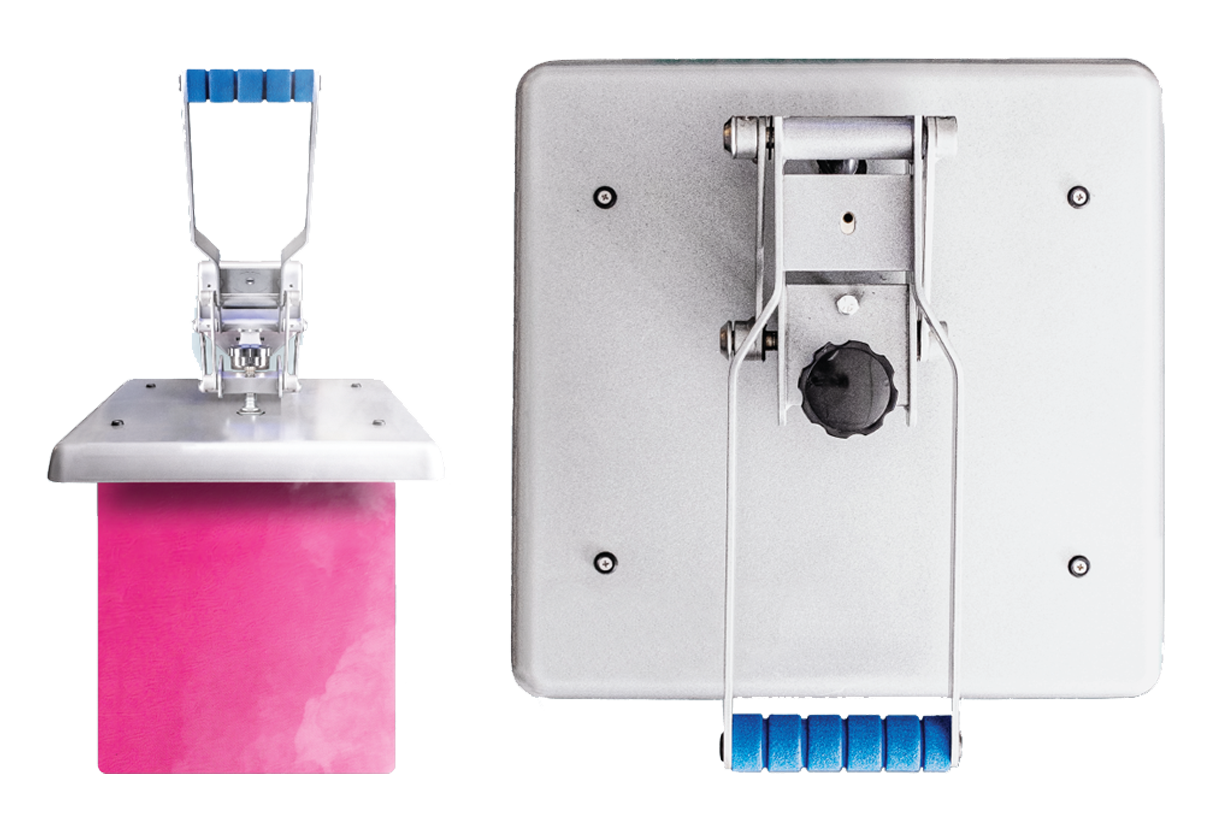

3. Load Garment

Open bottom of garment & slide

onto platen, making sure seams

are off the pressing area.

4. Pre-Press Garment

This removes moisture & wrinkles for a flat/dry pressing area

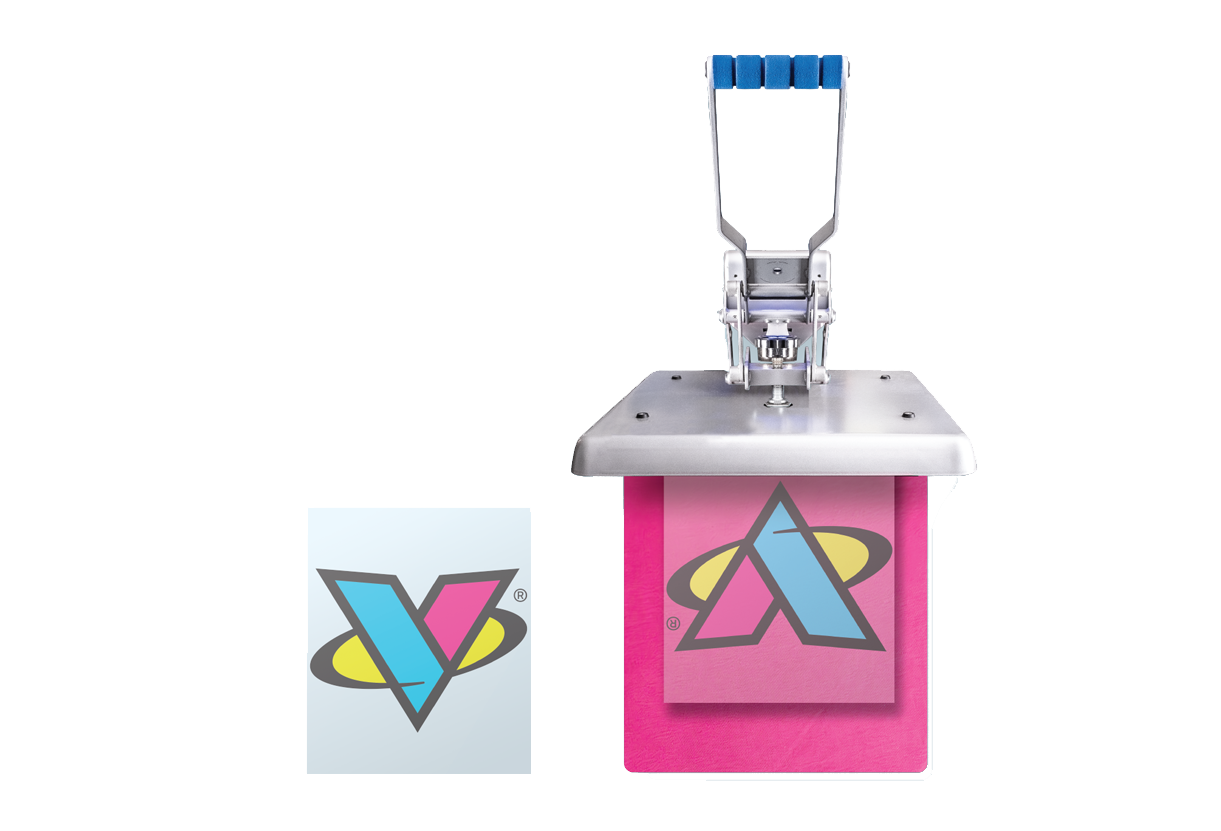

5. Position Transfer

Ensure transfer is not sitting on wrinkles, seams, or creases.

6. Press Transfer

According to material settings.

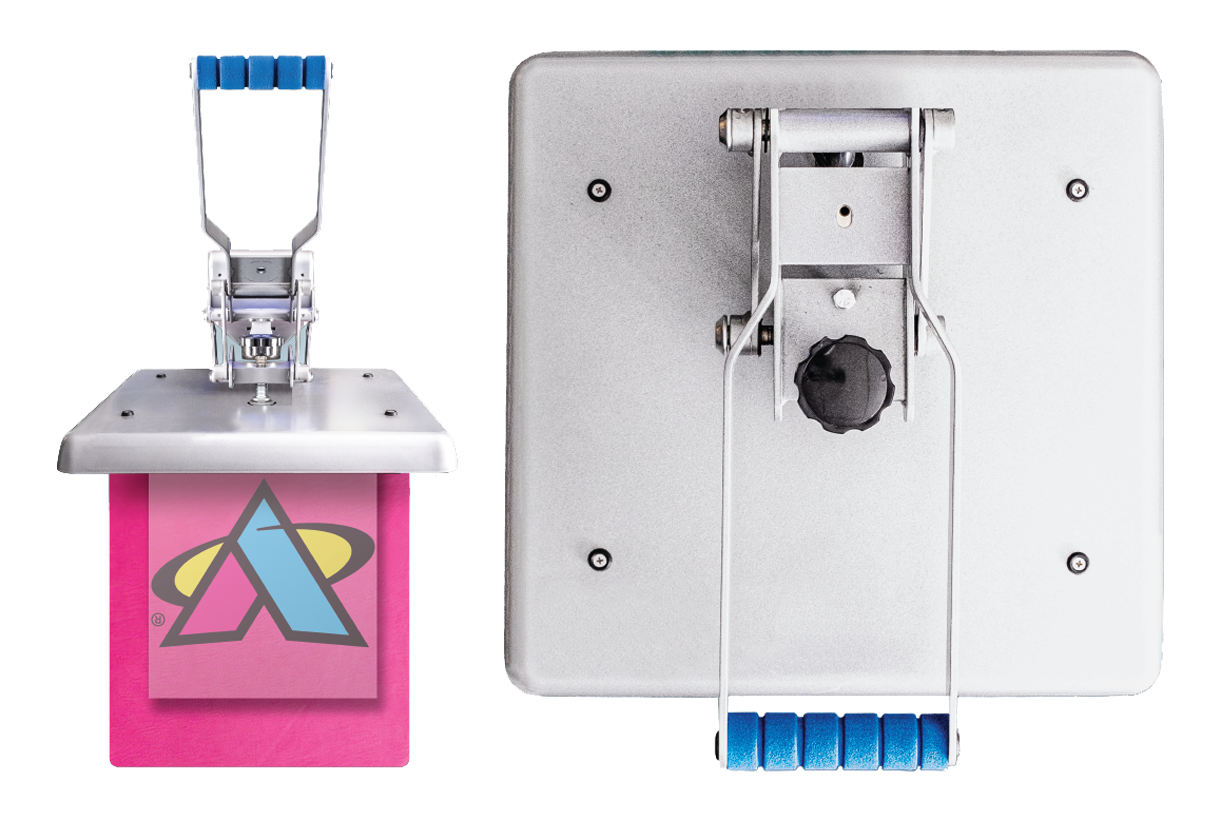

7. Peel Transfer

Peel with a smooth/steady motion.

Garment is Ready!

Washing Instructions

Machine wash warm.

Turn garment inside out

Do not bleach

Tumble dry ‑ medium heat

Do not iron

Heat Press Settings For DTF

For Non-Heat Sensitive Fabrics

(100% Cotton and Cotton/Poly Blends)

- Press Temp: 320°F

- Pressure: Medium/Heavy 6-8 (60psi)

- Time: 10-12 Seconds

- Peel Hot

For Heat Sensitive Fabrics

(100% Polyester, Tri-Blends, Spandex

Mesh, Nylon and Neoprene)

- Press Temp: 285°F

- Pressure: Medium/Heavy 6-8 (60psi)

- Time: 10-12 Seconds

- Peel Hot

For Low-Melt Materials

(Non-woven Polypropylene, PET)

- Press Temp: 270°F

- Pressure: Low/Medium 4-5 (40-50psi)

- Time: 10-12 Seconds

- Peel Cold